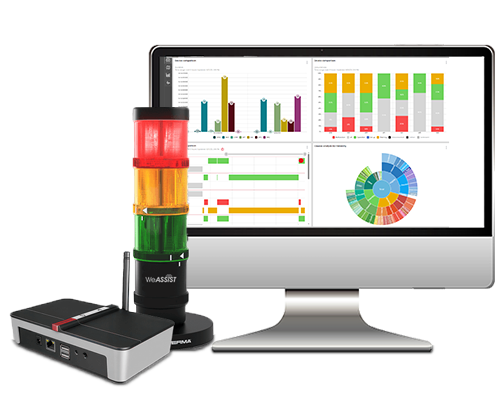

WeASSIST

The innovative plug & play solution

for comprehensive monitoring

of your production processes

The new generation: hardware and software

for process optimisation

Versatile in application

The digital twin

The WeASSIST transceivers pick up 24V signals from the WERMA signal towers and transmit them by radio to the WeASSIST gateway.

State analysis

Analysis of machine conditions helps to increase plant availability, reduce maintenance costs and improve productivity.

Capture disturbance reasons

The analysis of causes of malfunctions aims to minimize recurring problems in particular, improve product quality and reduce downtime.

Determination of overall equipment

effectiveness (OEE)

By continuously recording availability, performance and quality indicators, the overall equipment effectiveness (OEE) can be determined and broken down to individual machines, production lines or machine groups.

Advantages at a glance

Simple integration and retrofitting via a wireless module

The plug & play solution can be integrated directly in the desired department, as no extensive programming knowledge is required. The dashboard can be customised in a minute - without any support from the IT department. Existing signal towers can be easily upgraded to a complete solution via a wireless module.

Full transparency along the entire value chain

Scalable and ready-to-use retrofit solution for greater transparency of overall equipment effectiveness (OEE). Processes and systems are digitally mapped to continuously improve processes and minimise productivity losses.

Hardware and software from a single source

The ‘out-of-the-box’ solution from WERMA can be seamlessly integrated into your production processes. This means you always have an up-to-date overview of the order status, material bottlenecks and faults for quick, ad-hoc problem solving.

Successful in use

1.000

Customers worldwide

4.000

Applications

15 %

fewer unscheduled downtimes

from 1.500 €

start